Your one stop address for Materials Testing Technology and Innovative Construction Solutions

For over 28 years now the PGATECH Group has catered to the Construction and Materials Testing requirements of Philippine Companies. It is also involved in Professional Structural, Civil, Forensic and Geotechnical Engineering Design and Consultancy through its professional aim, EM²A Partners & Co.

In addition, PGA Calibration and Metrology Laboratory offers on site and at Laboratory Calibration Services for Pressure, Mass, Temperature, Length, Electrical, Torque and Load Calibration for Batch Plants and Testing Equipment.

We also supply innovative construction Geosynthetic Materials such as Geogrids and PP Gabions as well as pavement reinforcement.

The group also undertakes Non-Destructive Testing using X-Ray, Ultrasonic, Eddy Current, Magnetic Particle and Dye Penetrant Testing.

In the field of specialty foundation construction technologies, the PGATECH Group has pioneered in the introduction of Soil Nailing, Jet Grouting and Rammed Aggregate Piers RAP and IMPACT® Pier Technology.

PGATECH is also setting up in 2008 a fully equipped Vocational Training School to train Filipino Construction workers and Professionals in Construction Technology, Materials Testing and Quality Control, Welding Technology and other allied skills and trades.

Philippine GeoAnalytics, Inc.

FIRST ISO/IEC GUIDE 25 ACCREDITED LABORATORY

Philippine GeoAnalytics specializes in the Testing of Civil Engineering Materials & Soil Mechanics. It has extensive experience and capability in Construction Quality Control (CQC) at-site and operates a fleet of 16 Drilling Rigs for Soil Exploration. Four of these rigs are Truck Mounted Mobile Drills (B40 & B60) equipped with Hollow Stem Augers for Environmental Testing. It also tests construction materials such as Cements, Asphalt and Water quality.

EM²A Partners & Company

EM²A Partners & Company started as an A & E Department of the Parent Organizatio PHILIPPINE GEOANALYTICS, a single proprietorship company.The A & E Department was subsequently spun- off as a separate organization to concentrate on purely Professional Design & Consulting Activities. The company has been accredited as the very 1st Filipino Civil Engineering Consultancy Firm under ISO 9001 by TUV Cert of Germany.

EM² A Partners & Co. is a Multidisciplinary Consulting Engineering Firm engaged in Civil, Structural, Geotechnical, Materials, Forensic Engineering and CADD. Through the years, we have specialized in the Structural analysis and design of Industrial Facilities, Geotechnical Engineering, Site Civil Development and remediation measures for Derelict or Damaged Buildings as well as Design of Applications Programs for Information Technology applications using GIS . We are backed up by a complete Materials Testing Laboratory which is fully owned by the company. The Laboratory is the very first Soils and Materials Testing Laboratory accredited under ISO/IEC GUIDE 25. Our operations are fully computerized and we are among the pioneers in the Engineering Consultancy Business to operate a full CADD FACILITY. We have acquired the most powerful Structural Analysis and Design Software, STAAD III/ISDS to enhance efficiency and Structural Optimization. We have continually beefed up our capabilities through acquisition of Licensed Software to include the most powerful Civil Analysis Software, AUTOCIVIL capable of precise Earthwork computations, Digital Terrain Modeling, contouring, Surveying, Roadway Design, Storm Drainage Design, Sewer Design and Water Distribution Network Design. In addition, we have acquired Intergraph's SELECTCAD a sophisticated Stormwater and Sewer Analysis and design Program. We have also acquired the PCA Software MATS for design and analysis of MAT Foundations using Finite Element Analysis. We also have Scanning & Intelligent vectorizing Software to convert Drawings and Plans to CAD format. EM²A also makes use of Cad Manufacturing Solutions' popular IntelliCADD software for general CADD application. We use Intergraph's GEOMEDIA Software for Information Technology applications.

Services

Structural Engineering

- Structural Failure Analysis Design

- Structural Analysis and Design

- Structural Optimization & Value Engineering Services

Geotechnical Engineering

- Settlement Analysis

- Slope Stability Analysis

- Ground Instrumentation & Monitoring

- Soil Reclamation

- Soft Soil Engineering & Utilization of marginal lands

Civil Design & Site Development

- Site Development Planning

- Software Development

Computer Aided Design

- Software Development

Topographic Design

- GPS Topographic Survey TRIMBLE RTK Equipment

Sample Projects

Peter Ground Improvement, Inc.

Peter Ground pioneered new foundation technologies in the country like Jet Grouting & Soil Nailing. Jet Grouting is an in-site soil stabilization procedure and consist of injecting cement slurry at ultra high pressure to form cylindrical soil cement columns known as “Soil Crete” Soil Nailing is an effective solution to stabilization of open cuts in soils, weathered rock, and as a temporary or permanent retaining structure.

Services

- Soil Nailing

- Soil Stabilization

- Foundation Engineering and Construction

- Jet Grouting (underpinning, impermeability, foundation support)

- Soil and Rock Anchor Installation and Testing

- Chemical Grouting

- Unidirectional Grouting

Note: Jet Grouting is currently used worldwide as seepage Barriers and Co-barriers aside from its vertical load carrying capability.

PGA Calibration & Metrology Laboratory

PGA Calibration & Metrology Laboratory is the most fully equipped commercial calibration and metrology laboratory in the country today. PGA’s equipment have trace ability traceable to US NIST and other international “Standards” bodies. Thus far, our Secondary Transfer Standards have the highest accuracy and stability.

PGA offers a range of calibration services both for at-site or in-house laboratory testing. Our calibration procedures are all fully computerized and performed using OEM software to assure fast reliable accurate & error-free calculations and results.

With PGA, you won’t miss out on your next calibration date as we maintain Calibration Recall Software to remind you when your equipment is due for calibration.

Non Destructive Testing Laboratory

Non Destructive Testing Laboratory possess the most extensive testing equipment inventory for Non-destructive testing in the country. It has experienced and trained personnel, backed by a metallurgist to handle on-site and at-laboratory testing of Welds and Metal components. NDTL is the only laboratory (in the country) equipped with Rotating Eddy Current Testing Equipment.

Services

- Non destructive

- Ultrasonic Testing

- Thickness Gauging

- Conductivity Testing

- Dye Penetrant Testing Radiographic Testing

- Rotating Eddy Current Testing

- Non metallic Board Testing

- Magnetic Particle Testing

- Metallurgical Consultancy

- Qualification of Welders

- Specialized Technical Training Center

- Consultancy on Laboratory Setup based on ISO/IEC Guide 25

- Metallurgical Testing

- Tension/Compression/Bend Testing

- Materials Characterization

- Metallurgical Analysis of Components Failure

- Fillet break test for weldments

PGA Environmental, Inc.

PGA Environmental has complete monitoring and testing equipment for Hazardous Waste and toxic substances. The company can draw from the expertise of it’s American partners who have had extensive experience in Bases cleanup and remediation of toxic waste contaminated sites. PGA Environmental also provides training in safety and handling of hazardous waste.

- Hazardous area entry for tank inspection (SCBA & Airlines)

- Site remediation studies

- Safety training

- Respiratory Protection

- Ear protection program

- Hazardous material

- Fall protection program

- Eye protection program

- Back injury prevention

- Electrical safety lockouts and tagouts

- Hazardous waste monitoring and testing

- Environmental Training

- Environmental Monitoring

- Gas detection

- Ground level monitoring

- Air particle monitoring

- Air velocity sampling

- Microwave leak testing

- Sound level monitoring

- Site contamination training

- PCB's

- Hydrocarbons

- Trace metal

PGA Product Testing Laboratory

PGA Product Testing Laboratory is equipped with state-of-the-art equipment for testing of Automobile and Truck tires initially for the Bureau of Product Standards. It will soon branch out in the testing of other consumer products such as packaging and electrical products.

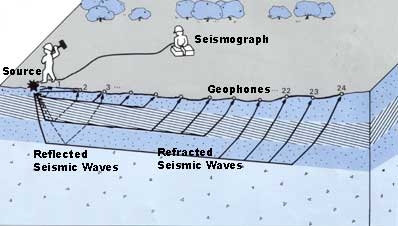

PGA Geophysical

PGA Geophysical offers top of the line technology for detailed stratification, characterization and mapping of the subsurface using non-invasive techniques. It specializes in extensive surveys and field reconnaissance work, the detection of geotechnical anomalies and fast site characterization.

Services

- Conduct Geophysical Surveys to include Soil Resistivity Testing, Borehole Resistivity and Borehole Caliper Tests

- Seismic Refraction Tests

- Corrosion Study Tests

PGA Geopier

PGA GEOPIER is the exclusive Philippine Licensee and authorized installer of GEOPIER® soil reinforcement system. The innovative GEOPIER ground improvement technology has been used worldwide since 1989. It has been proven to save construction time and cost, while providing a predictably reliable end product. The technology involves ramming aggregates in layers to prestress and prestrain the surrounding soil to mobilize and increase its bearing capacity. The stiffened GEOPIER® elements and the improved matrix soils provide a reinforced composite zone to support the structural loads.

Applications

GEOPIER soil reinforcement system,The Rammed Aggregate Pier® and Intermediate Foundation® Systems are used to:

- Increase soil bearing capacity and support shallow footings on poor, marginal, or fair soils; alternate to deep foundations or massive overexcavation and replacement with short (3-8 meters long) GEOPIER aggregate columns.

- Support floor slabs over unsuitable soils.

- Reinforce soft foundation soils for transportation applications - embankment and retaining wall.

- Stabilize landslides.

- Support steel storage tanks.

- Control soil liquefaction.

- Provide tensile resistance using uplift anchors.

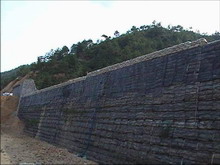

PGA-Earth Structure Solutions

PGA-Earth Structure Solutions is a subsidiary of PGA Group of Companies. Our company provides engineering support and structural stability design assistance for MSE Wall retaining structures using Geogrids. PGAESS also provides impartial advice on your civil engineering projects that involves ground stability and settlement problems, from application suggestions and product type selection, to on-site advice and construction guidance for more efficient and most cost-effective solutions to your construction problems. The use of E'GRID Geogrids as Soil Reinforcement Solutions is one of the best alternative solutions compared to the use of conventional solutions like RC Walls,Gabion Gravity Walls and Stone Masonry and Riprap Retaining Walls. The PGA-ESS E'GRID Reinforced Soil System Solutions can help you save up to 40% of your original cost using the old old conventional methods.

PGA-ESS holds the Philippines Distributorship of E-GRID Geogrids. E-GRID is a registered trademark and is an internationally accepted geogrid product and meets ISO Standards for strength and creep characteristics and has been granted the prestigious CE mark. It has found wide acceptance in Europe, Australia, New Zealand, China, and Southeast Asia.

Products

INTEGRAL HDPE UNIAXIAL GEOGRIDS

Chemical, Biological and UV Properties

E’GRIDS are manufactured by stretching High Quality punched sheets of engineering grades of polymers under closely controlled conditions. The structures of optimised nodes ribs and bars that this produces have a significant effect on the spreading of loads in soils. Generally a polymer has molecular chains distributed randomly with similar properties in all directions.

The principle of manufacturing punched and stretched Geogrids relies upon greatly improved mechanical properties in the direction of orientation. The orientation improves polymer strength.

The control of orientation in the nodes has a significant effect on the tensile properties and creep performance of the grid. This feature has been optimised in E’GRIDS. Orientation gives a stable arrangement of the polymer molecular chains resulting in improved tensile modulus. Orientation also greatly reduces strain under long-term constant loading, essential dimensional stability in construction work.

Resistance to Ultra-Violet Light

A high level of resistance to Ultra-Violet Light is given to E'GRID Geogrids by the incorporation of =2% of weathering-grade Carbon Black, well dispersed in the polymer matrix. These products may be used for many years in exposed conditions.

Creep Performance

A good creep performance under sustained loading is essential for the use of geogrids in critical structures such as walls, abutments and steep embankment. Qingdao E'GRID Geogrids Co,Ltd maintains constant Creep testing programmes in its laboratories works closely with National and International experts in the performance of geogrids to ensure that its products meet the strictest demands in all markets.

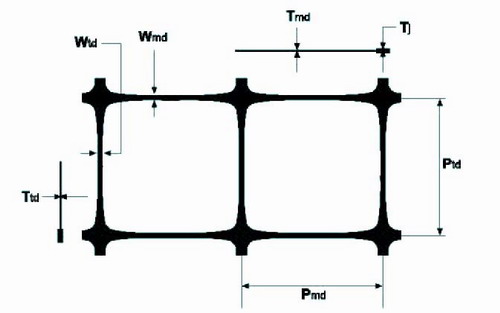

PP BIAXIAL GEOGRIDS

The properties of E'GRID PP Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Typical Dimensions in mm

The reinforcing action of E’GRIDS lies mainly in increasing the shearing resistance within a soil by a process of interlocking between the square ribs and the soil.

The load dispersal effect from the interlocking mechanism is more effective and can reduce sub-base thickness and construction cost. E’GRIDS can be used with any kind of fill material.

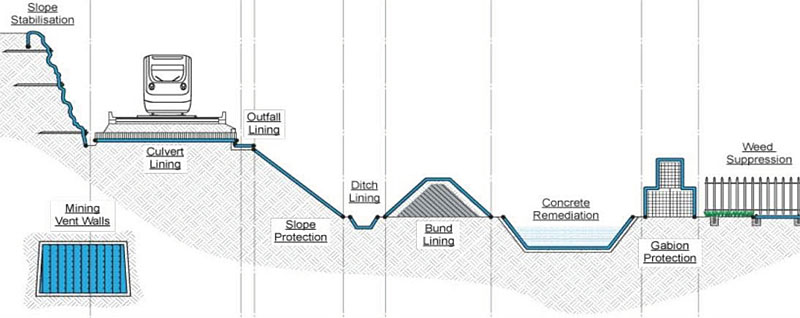

CONCRETE CANVAS TM

Concrete CanvasTM (CC) is a flexible, concrete impregnated fabric that hardens when hydrated to form a thin, durable, water proof and fire resistant concrete layer. CC allows concrete construction without the need for plant or mixing equipment. Simply position the Canvas and just add water.

Concrete CanvasTM consists of a 3-dimensional fiber matrix containing a specially formulated dry concrete mix. A PVC backing on one surface of the Canvas ensures the material is completely water proof. The material can be hydrated either by spraying or by being fully immersed in water. Once set, the fibers reinforce the concrete, preventing crack propagation and providing a safe plastic failure mode. CC is available in 3 thicknesses: CC5, CC8 and CC13, which are 5, 8 and 13mm thick respectively.

CC User Benefits:

- Rapid Install – CC can be laid at the rate of 200 sqm/hour, up to 10 times faster than conventional concrete solutions.

- Easy to Use – CC is available in man portable rolls for applications with limited access. The concrete is pre-mixed so there is no need for mixing, measuring or compacting. Just add water.

- Lower Project Costs – The speed and ease of installation mean CC is more cost-effective than conventional concrete, with less logistical complexity.

- Eco-Friendly – CC is a low mass, low carbon technology which uses up to 95% less material than conventional concrete for many applications.

CC Key Properties:

- Water Proof – The PVC backing on one surface of the Canvas ensures that the material has excellent impermeability.

- Strong – The fiber reinforcement prevents cracking, absorbs energy from impacts and provides a stable failure mode.

- Durable – CC is chemically resistant, has good weathering performance and will not degrade in UV.

- Flexible CC has good drape characteristics and will closely follow the profile of any ditch or embankment. The material can negotiate tight bends and fit around existing infrastructure. Unset CC can be cut or tailored using the basic hand tools.

CC Applications:

- Ditch Lining – CC can be rapidly unrolled to form a ditch or channel lining. It is significantly quicker, easier and less expensive to install than conventional concrete ditch lining and requires no specialist plant equipment. CC can be laid at a rate of 200sqm/hr. by a 3 man team.

- Slope Protection – CC can be used to stabilize and protect slopes as a replacement for shotcrete and steel mesh. It is typically faster to install, lower cost and requires less specialist plant equipment. CC also helps eliminate the risks associated with shotcrete rebound and debris.

- Bund Lining – CC provides a cost-effective alternative to poured or sprayed concrete for lining secondary containment bunds. It acts as an effective weed barrier, reducing maintenance costs as well as providing additional levels of impermeability and fire protection. Its ability to be installed quickly reduces time on site, while the availability of man-portable rolls allows for installation in areas with reduced access.

- Remediation – CC can be used to rapidly reline and refurbish existing concrete structures suffering from environmental degradation and cracking.

- Culvert Lining – CC can be used as a cost-effective alternative to bitumen spraying or re-building damaged culverts, while offering a durable means of providing erosion protection.

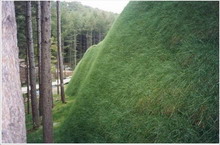

E’GRID 3D EROSION MAT

E’GRID 3D EROSION MAT is a robust, high tensile strength, threedimensional structure with outstanding drape qualities, which enables it to conform to and maintain intimate contact with the soil profile. With the E’GRID 3D Erosion Mat completely filled with soil, and with an established grass root system, a tenacious and permanent erosion resistant cover is provided to slope, banks and bunds.

E’GRID 3D Erosion Mats are use for sites where turf cannot stand up to high velocity flow and where riprap and concrete paving is unacceptable or overkill. E’GRID 3D Erosion Mats are multi-layered polyethylene netting that reinforces the turf of grassed waterways and slopes against washout. E’GRID 3D Erosion Mats are effectively used on lakeshores, reservoirs, riverbanks, riverbeds, and ditches, slopes of dykes, and road embankments and cuttings

CeTeau PVD DRAINS

PREFABRICATED Vertical Drains (PVDs) are artificially created drainage paths which are installed to accomplish the following objectives: a) to accelerate the consolidation process of soft, saturated clays and b) to expedite strength increase to improve the stability of embankments built on weak clay subsoil. Most PVDs are bands consisting of a synthetic Geotextile jacket surrounding a plastic core. The jacket functions as a physical barrier separating the core flow channels from the surrounding fine-grained soils and likewise serves as a filter to limit the passage of fine grained material into the core of the drain. The core, on the other hand, provides structural support for the jacket and provides longitudinal flow paths along the drain length.

PGA – Earth Structure Solutions, Inc. has tied up with CeTeau foryears now, one of the world’s leaders in the manufacture and installation of PVD drains and horizontal strip drains. CeTeau is equipped with some of the world’s fastest and strongest stitchers with complete quality control monitoring systems, fastest stitchers and computerized data loggers.

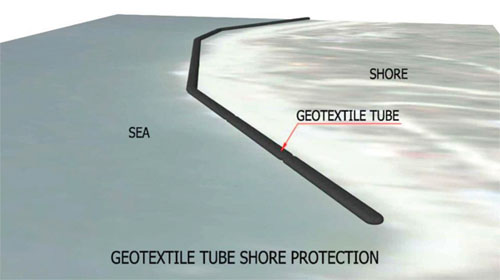

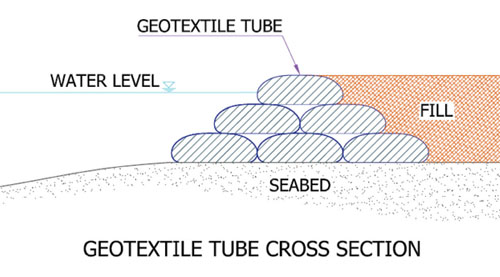

GEOTEXTILE TUBES

Geotextile tubes are fabricated woven geotextile tubes that provide robust solutions to a wide range of engineering applications where dewatering of soils and sediments is required. Some of the common applications are:

- Coastal / Shoreline Protection and Remediation

- Land Reclamation

- Diversion Dikes and River Channel Realignment

- Marine Structure Applications

- Agricultural Applications

- Solid and Waste Containment

- Industrial Applications

- Containment of Hydraulic Fill

- Dewatering of Silted Bodies of Water / Reservoirs

OTHER GEOSYNTHETIC PRODUCTS

PGA – Earth Structure Solutions, Inc. offers different geosynthetic products that have been used in several projects worldwide.

- Geomembranes

- Geonets & Geocomposite Drains

- Geosynthetic Clay Liners

- Geotextiles (Non-woven and Woven)

- MSE Wall Panels

Applications

INTEGRAL HDPE UNIAXIAL GEOGRIDS

Uni-Axial E’GRID is meshes with elongated apertures made from high density polyethylene (HDPE) and generally used as reinforcement of walls and slopes. Their principle characteristic is good creep performance with low strain and high strength under constant load.

Walls and Abutment Reinforcement

E’GRID reinforced soil walls and abutments are composed of wall facing, and fill reinforced with E’GRIDS. They can be constructed quickly with simple technology, machinery and techniques and at low cost.

They are tough and elastic composite structures of purpose designed multiple layers on E’GRID and fill.

They can accommodate base deformation and have particularly good resistance to vibration and earthquakes. E’GRID reinforcement can improve the bearing capacity and factor of safety of a structure and reduce construction cost.

Steep Slopes

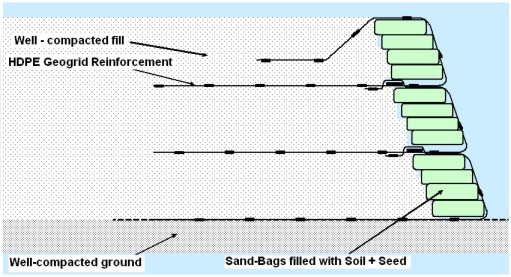

E’GRIDS can be used to construct steep slopes with a surface of natural vegetation. Construction involves rising the slope with E’GRID layered into the fill and wrapped around the face to the required slope angle. Using these technique safe structures with permanent vegetation faces can be built to integrate spent quarries into the local environment.

Reinforcement of Slopes

In construction of roads and railways, reduced land take, convenient construction, and good safety margins can be achieved by using E’GRID reinforcement. In environmentally sensitive areas, steep with vegetated slopes can often be built in place of the hard-faced structures such as brick, stone or concrete that would be needed with conventional techniques.

PP BIAXIAL GEOGRIDS

The properties of Etsong Bi-Axial E’GRIDS, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material. The reinforcing action of E’GRIDS lies mainly in increasing the shearing resistance within a soil by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is more effective and can reduce sub-base thickness and construction cost.E’GRIDS can be used with any kind of fill material.

Roads, railways, ports and other paved areas

One layer or multi–layer E’GRID construction distributes loading and disperses stress more effectively, leading to the reduction in differential settlement and improved foundation bearing capacity.

Airport Runways

A tough platform can be established with E’GRID reinforcement. Resistance to the impact of aircraft take off and landing is improved with more effective and immediate load dispersal.

Temporary roads and other un-paved areas

E’GRID reinforcement gives ease of construction of temporary pavements with reduced construction time and cost.

Biaxial Geogrids in road construction

Geogrid when used in road construction:

- Reduces differential settlement

- Improves load distribution

- revents mud pumping

- Interlocks with aggregates and prevents lateral movement of stones.

- Can have a saving of 30% on aggregate thickness

- Improves lifespan of roads

- Reduces maintenance costs

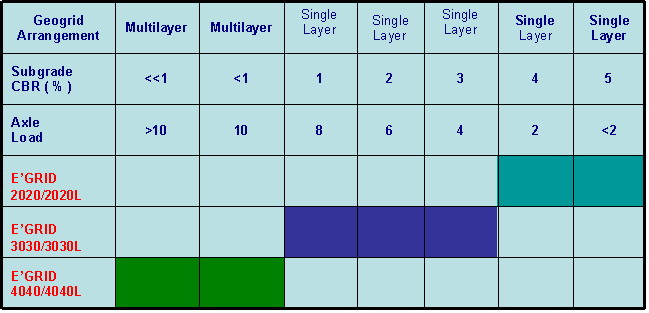

Geogrid Application Guide

Procedure

Construction Sequence for Bagwork-Faced walls with a Wrap-around face

- Prepare a level foundation (Well compacted Ground) as required in preparation for the laying of the first Geogrid Layer.

- Cut and position the base layer of grid leaving the wrap-around grid length proud of wall face. Grids should be installed to the level, lengths and orientation as shown in the Construction drawings.

- Place two or three courses of bags which have been filled with garden soil.

- Place a quantity of fill on the grid close to the rear of the bags, pull the grid or stretch it tightly at the free end and secure with fill.

- Place and compact fill in layers behind bagwork (95% compaction) to the level of the next layer.

- Compact to DoT Specification for Highway Works (2001). Use a vibrating plate compactor or a vibrating roller with a mass per meter width = 1000kg.

- Fold the wrap-around grid length around the bagwork (at specified distance of each layer of the grid) and lay it over the surface of the fill.

- Cut and position the next layer of grid. Form a joint between this and the ower grid length (see figure) using a suitable bodkin (see bodkin for specification detail).

- Apply a load to the free end of the upper grid, using a wooden pegs inserted through the apertures of the geogrids, until the slack is removed from the joint and the lower grid is pulled tight around the bag.

- While maintaining tension, place a layer of fill on the grid which will be sufficient to restrain it when the load is removed.

- Repeat the sequence up to the design height of the structure.

- The top layer of grid is provided with a longer wrap-around length which is secured by burying beneath the top surface with sufficient surcharge to restrain it permanently ( see main figure).

- The contractor must carefully assess the safety risk associated with working at height and where appropriate install any necessary temporary edge protection.

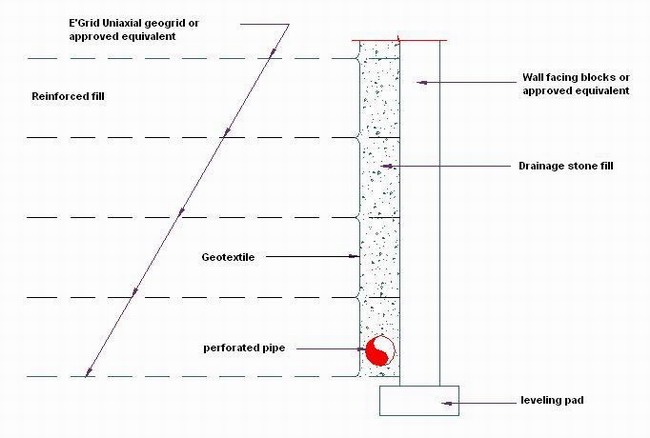

Construction Sequence for Block facing walls

- Prepare the leveling pad and lay the base course of the blocks, ensure that the units are level front to back, side to side and to the correct alignment. Align the blocks with a string line placed on top of the blocks. Allow the mortar bed to cure before laying additional courses.

- Place a quantity of drainage layer at the back of the blocks and place a geotextile to ensure separation fill and drainage layer. Place fill up to the layer of reinforcement and compact (95% compaction).

- Stretch the embedded “tail” of the Geogrid and fastened it to the reinforcement layer using a Bodkin (as shown in the drawings).

- Stretch the “tail” of the reinforcement to the design anchorage length and place wooden peg to ensure tension. Place a quantity of fill up to the next layer of reinforcement and compact (95% compaction).

- Repeat steps 2, 3 and 4 up to the design height of the wall.

Contact Us

PGA Group of Companies

Address: PGA Technical Center, 85 Kamuning Rd, Diliman, Quezon City, 1103 Metro Manila

Phone: (+632) 929-3352 to 55 | (+632) 929-1780

Fax: (+632) 929-3353

E-mail: pgamain@gmail.com

Find us on Google Maps

sponsored links

SIMILAR COMPANIES/PRODUCTS/SERVICES

Terms of Use/Privacy Policy Advertise Buy me coffee