KIMIKA Industrial Corp. was founded on March of 1976, and for over 35 years, the company has maintained its credibility of supplying its customers with high quality materials for their various needs. KIMIKA has established itself as one of the leading supplier of engineering plastics, carrying an extensive range for almost all types of industrial applications: food & beverages manufacturing, material handling, conveyor systems, electronics assembly, chemical processing and many more.

Products

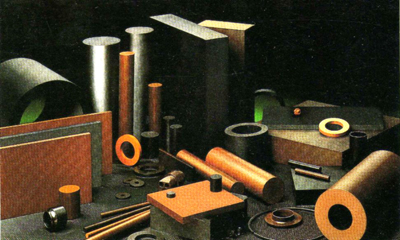

ENGINEERING PLASTICS

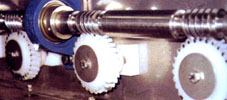

NYLON [PA: Polyamide]

Nylons are used in a wide range of industrial components both for Original Equipment Manufacturing and maintenance.

Main Characteristics:

- High mechanical strength, stiffness, hardness and toughness

- Good fatigue resistance

- High mechanical damping ability

- Good sliding properties

- Excellent wear resistance

- Good electrical insulating properties

- Good resistance to high energy radiation (gamma- and X-rays)

- Good machineability

Applications:

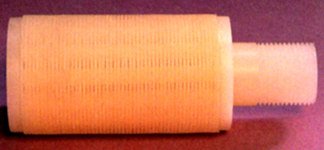

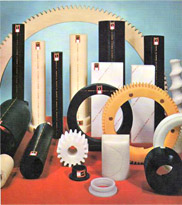

Sleeve and slide bearings, wear pads, support and guide wheels, conveyor rollers, tension rollers, pulley and pulley-linings, cams, buffer blocks, hammer heads, scrapers, gear wheels, sprockets, feed screws, star wheels, seal-rings, cutting and chopping boards, insulating components for electrical engineering.

ACETAL [POM:Polyacetal]

This is very well suited for machining on automatic lathes and is particularly recommended for mechanical precision parts.

Main Characteristics:

- High mechanical strength, stiffness and hardness

- Excellent resilience

- Good creep resistance

- High impact strength, even at low temperatures

- Very good dimensional stability (low water absorption)

- Good sliding properties and wear resistance

- Excellent machinability

- Good electrical insulating and dielectric properties

- Physiologically inert (suitable for food contact)

- Not self-extinguishing

Applications:

Gear wheels with small modulus, cams, heavily loaded bearings and rollers, bearings and gears with small clearances, valve seats, snapfit assemblies, all kinds of dimensionally stable precision parts for machine construction, electrically insulating components, parts which operate continuously in water of 60 - 80°C.

ERTALYTE [PET: Polyethylene Terephthalate]

This is made of crystalline polyester with properties characterized by high rigidity and strength. Abrasion resistance is higher than those of Nylon and Acetal.

Main Charactertictics:

- High mechanical strength, stiffness and hardness

- Very good creep resistance

- Low and constant coefficient of friction

- Excellent wear resistance (comparable with or even better than nylon grades)

- Very good dimension stability (better than polyacetal)

- Excellent stain resistance

- Better resistance to acids than nylon and polyacetal

- Good electrical insulating properties

- Physiologically inert (suitable for food contact)

- Good resistance to high energy radiation (gamma- and X–rays)

Applications:

Heavily loaded bearing (brushings, thrust washers, guides, etc.), dimensionally stable parts for mechanism of precision (brushings, slideways, gears, rollers, pump components, etc.) and insulating components for electrical engineering.

HDPE [high density polyethylene]

Outstanding impact resistance and tensile strength making it the perfect choice for a wide range of applications such as: tanks and vessels, food cutting boards, light-duty tank, chute and bin linings, playground structures, restroom partitions and boat accessories

Main Characteristics:

- Meets FDA/USDA food handling guidelines (natural color)

- Chemical- and corrosion- resistant

- Light-weight

- No moisture absorption

- High tensile strength

- Non-toxic

- Non-staining

- Thermoforming performance

Applications:

Light duty chain guides, Orthotic and prosthetic devices, Secondary containment, Tanks, Thermoformed material handling devices, Water storage

UHMW-PE [PE1000:ultra high molecular weight polyethylene]

UHMW-PE sets the standard for engineered polymers with a unique combination of wear and corrosion resistance, low friction surface and impact strength. It is resistant to chemical attack and moisture absorption, and retains key physical properties to -30° C.

Main Characteristics:

- Very good wear and abrasion resistance

- High impact strength, even at low temperatures

- Excellent chemical resistance

- Low coefficient of friction

- Moderate mechanical strength, stiffness and creep resistance

Applications:

FOOD, BEVERAGE, BOTTLING and PACKAGING INDUSTRY.

The excellent abrasion and chemical resistance in addition to the ability to absorb noise makes it ideal for applications such as:

- star wheels and corner guides

- chain and belt guides

- idler sprockets

- guide rails and rollers

- bin and mixer linings

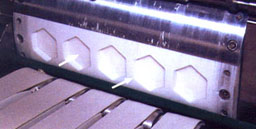

CONVEYING INDUSTRY

Today's high speed conveyors demand surfaces with a low coefficient of friction combined with excellent impact and abrasion resistance. UHMW-PE is ideal for the following applications:

- straight and curved tracks

- wear strips and guide rails

- rollers and roller sleeves

- gears and sprockets

- pillow blocks

Okuslide UHMW-PE Dump Truck Liner/Linings

KIMIKA, now offers a range of OKUSLIDE ultra-high molecular weight polyethyene (UHMWPE) linings to help increase efficiencies in various transport and loading applications.

Main Characteristics:

- Offer high abrasion resistance

- High resistance to UV, impact and a large number of acids and caustics

- Can operate in extreme environments at sub-zero temperatures as low as -40 degrees C

- Low coefficient of friction and low water absorption

- Quicker disposition of the contents to the desired location

- Flame resistant

Applications:

Various industrial sectors ranging from mining, farming, maritime, coal and electrical to petrochemical, power and defence. Recommended for silos, railcars, receiving bunkers and hoppers in coal mining or farm segments.

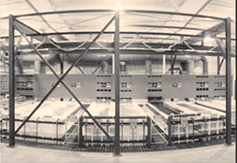

PP [Polypropylene]

Best known for its outstanding chemical resistance, polypropylene is easily fabricated, welded and machined for many different applications, particularly in chemical engineering and tank building and medical and clean room technology.

Main Characteristics:

- High strength

- Very high heat resistance

- Excellent weldability properties

- High chemical and corrosion resistance

Applications:

- Chemical engineering and tank building

- Plating barrels

- Galvanotechnology

- Ducts, fume hoods, ventilation and equipment manufacturing

- Laboratory technology

- Semiconductor processing equipment

PVC [Polyvinyle Chloride]

Rigid Polyvinylchloride is rated self-extinguishing, has an exceptional chemical resistance and is easy to machine. PVC shows high mechanical strengths, tensile strength and can be used in applications ranging in temperature from -15 °C to +60 °C. It can also be easily solvent cemented and welded.

Main Characteristics:

- High chemical resistance

- High mechanical strength, tensile strength and hardness

- Self-extinguishing

- Low water absorption

- Easy to varnish, glue and weld

- High impact strength

- Limited weather resistance

Applications:

PVC is used in pipes for water systems and as sheets and bars for acid-resistant tanks, photo development trays, chemical apparatus, fuse boxes, and the like.

C-PVC (chlorinated PVC)

It has a much higher temperature resistance than ordinary PVC and can be used in the temperature up to +105ºC.

ACRYLIC PLEXIGLAS [PMMA]

Acrylic or Plexiglas comes up for discussion as a technical construction material everywhere when a completely uninterrupted view is required. Optical purity, high strength and good chemical resistance make acrylic a widely used material for liquid meters and site glass.

Main Characteristics:

- High optical quality

- Extremely high light transmission

- Unsurpassed for resistance to aging and weather

- Substantially resistant to chemical attack

POLYCARBONATE

Polycarbonate is a transparent thermoplastic which offers very high impact strength and high modulus of elasticity. The material has a 145°C heat deflection temperature at 264 psi, absorbs very little moisture and resists acidic solutions. These properties, in addition to good electrical characteristics, make polycarbonate an excellent choice for electrical / electronic applications. Its strength, impact resistance and transparency also make it an ideal material for transparent structural applications such as sight glasses and windows.

Main Characteristics:

- High mechanical strength

- Good creep resistance

- Transparent

- Very good dimensional stability

- Stiffness retention

- Very high impact strength even at low temperature

- Physiologically inert (suitable for food contact)

Typical Applications:

- Vandal resistant windows

- Machine covers

- Outdoor signs

- Skylights

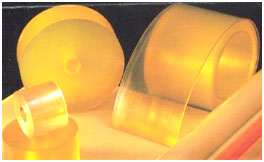

POLYURETHANE

This is an elastometric material of exceptional physical properties, toughness, and flexibility, resistant to abrasion, puncture resistance, and broad range of hardness.

Main Characteristics:

- Machineability

- Hydraulic stability

- Low temperature stiffening

- High-load bearing capacity

- Extraordinary resistance to abrasion

- Hardness and resilience

- Low coefficient of friction

- Good impact resistance

Application:

- Rolls: guide, drive, pinch, etc.

- Sheave linings

- Piston cups and seals

- Gaskets

- Bushings

- Wear pads

- Pump liners and impellers

- Liners for chutes

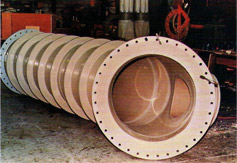

- Lining for slurry pipes and fittings

- Conveyor rollers

- Filter screens

- Industrial tyres

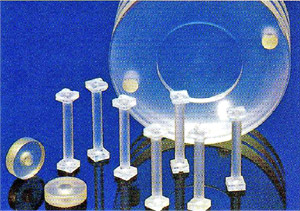

TEFLON [PTFE]

Teflon (PTFE) is a high molecular weight polymer. This is one of the most versatile plastic materials known and useful for a large range of products, for applications excluded to other materials. PTFE can be employed at any temperature from -150 ºC to +260 ºC.

Main Characteristics:

- High heat resistance

- High resistance to chemical agents and solvents

- High anti-adhesiveness

- High dielectric properties

- Non-toxicity

- Low coefficient of friction

Applications:

- VALVE FITTINGS. Sealing rings and guides, dail seats. Packing / gaskets, plugs, bushes, impellers, washers, pistons, guide segments and sealing in general.

- MECHANICAL APPLICATIONS. Self-lubricating bearing, piston rings, hydraulic seals, "O" rings, anti-extrusion rings, sliding shoes, expansion bellows, pressure compensators, friction washers, flow regulators, sputter devices, sandwich seals, roller, balls, packs, collars.

- CHEMICAL APPLICATIONS. Conduits, siphon pipes, retainer rings, floe seals, closing taps, magnetic agitators, laboratory recipients, dilation compensators.

- ELECTRICAL APPLICATIONS. Connectors, coil separators, insulators, electronics in general, terminals, insulating layers, high voltage wiring, coaxial radar and TV cables.

PTFE Reinforced Filled Grades

PTFE is a soft material that it can experience rate of wear when used in dynamic situation. Inert fillers could be added to increase resistance to wear, deformation and creep. It will improve stiffness, thermal conductivity, hardness and dimensional stability. However, the fillers decrease properties such as tensile strength, elongation, and dielectric values.

Available Fillers:

25% Glass Filled , 25% Carbon Filled, 60% Bronze Filled

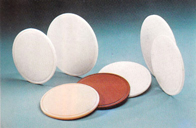

PE CHOPPING BOARDS

Kimika's chopping boards are made from food grade high molecular weight polyethylene (HMW-PE). These chopping boards are extensively used for the processing and preparing of foods in such sectors as hotels, restaurants, butchers, abattoirs, poultry, cheese-vegetable processors and fish processing factories.

The advantages are easily obtainable:

- High grade quality plastic

- Non-absorption of liquids

- Tasteless and hygienically unobjectionable

- Gentle to the cutting instruments

- Easily to clean

Although most of the cutting boards are in neutral (white), special colors can be supplied to segregate meat, poultry, fish and vegetables.

HIGH PERFORMANCE PLASTICS

PEEK

Most popular advanced plastics material due to unique combination of high mechanical properties, chemical and temperature resistance (continuously to 250°C).

- Excellent chemical resistance

- Very low moisture absorption

- Inherently good wear and abrasion resistance

- Unaffected by continuous exposure to hot water or steam

KETRON PEEK - 1000 natural (brownish grey) and black This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

Other PEEK variants:

- KETRON PEEK HPV (Carbon fiber reinforced with graphite and PTFE lubricants)

- KETRON PEEK GF30 (30% Glass-Reinforced)

- KETRON PEEK CA30 (30% Carbon Fiber-Reinforced)

TORLON [PAI:polyamide-imide]

For high temperature applications, this advanced material offers an excellent combination of mechanical performance and dimensional stability.

- Very high maximum allowable service temperature in air (250°C continuously)

- Outstanding UV-resistance and excellent resistance against high enery radiation

TORLON 4203 PAI yellow-ochre

Torlon 4203 PAI offers the best toughness and impact strength of all Torlon PAI grades. It is very popular for precision parts because of its high temperature resistance, high dimensional stability and good machinability. Its good insulating ability provides numerous possibilities in the field of electrical components.

TORLON 4301 PAI black

The addition of PTFE and graphite provides higher wear resistance and lower coefficient of friction compared to the unfilled grade. This grade excels in severe wear applications such as non-lubricated bearings, seals, bearing cages and reciprocating compressor parts.

TORLON 5530 PAI black

This 30% glass fiber reinforced grade offers higher stiffness, strength and creep resistance than Torlon 4203 PAI.

ULTEM [polyetherimide]

Ultem l000 polyetherimide (PEI) performs continuously to 170°C, making it ideal for high strength and high heat applications, and those requiring consistent dielectric properties over a wide frequency range. It is hydrolysis resistant, highly resistant to acidic solutions and capable of withstanding repeated autoclaving cycles.

- Excellent chemical resistance

- Very low moisture absorption

- Inherently good wear and abrasion resistance

- Unaffected by continuous exposure to hot water or steam

VESPEL [polyimide]

Vespel SP are made from DuPont SP-Polyimide offer a combination of properties that allows them to excel in applications requiring low wear and long life in severe environments.

Allowable service temperature from 255°C up to 480°C for short periods.

VESPEL SP-1 natural (chestnut)

This is the unfilled base resin that provides maximum physical properties and the best electrical and thermal insulation. It is frequently used as valve seats, seals, and insulators working at elevated temperatures.

VESPEL SP-21 grey-black

This grade contains 15% graphite, added to provide long wear and low friction. These features make VESPEL SP-21 ideal for bearings, thrust washers and dynamic seals.

PPS [polyphenylene sulphide]

Techtron HPV PPS is a reinforced, internally lubricated semi-crystalline polymer developed to close the gap both in performance and price between the standard thermoplastic materials.

- Broadest range of chemical resistance

- Excellent alternative to PEEK at lower temperatures

PSU [polysulphone]

PSU 1000 Polysulfone (PSU) offers very good radiation stability, low ionic impurity levels and good chemical and hydrolysis resistance. Compared to PEI-1000, it has a lower property profile, often replacing polycarbonate whenever higher temperature resistance and improved chemical resistance.

PPSU 1000 [polyphenylsulphone]

PPSU 1000 are produced from RADEL R resins. It offers a better impact strength and chemical resistance than PSU 1000 and PEI 1000. PPSU-1000 also has superior hydrolysis resistance as measured by steam autoclaving cycles to failure. In fact, this material has virtually unlimited steam

PVDF [polyvinylidene flouride]

PVDF-1000 is a highly crystalline unreinforced fluopolymer combining good mechanical, thermal and electrical properties with excellent chemical resistance. It also shows good resistance to high –energy radiation. PVDF-1000 is a versatile engineering plastic material especially suitable for the manufacture of components for the petro-chemical, chemical, metallurgical, food, paper, textile, pharmaceutical and nuclear industries.

FLOUROSINT [reinforced PTFE]

FLUOROSINT has parallel chemical resistance compared to PTFE but higher load carrying capability, lower coefficient of thermal expansion and 1/9 of PTFE's deformation under load. Continuous use temperatures to 260°C.

ANTI-STATIC PLASTICS

SEMITRON ESD

The Semitron ESd family of static dissipative products is designed for applications where electrical discharge in operation is a problem. They are commonly used for sensitive electronic components including: integrated circuits, hard disk and circuit boards. Semitron products are also an excellent choice for material handling applications, and components in high speed electronic printing and reproducing equipment.

Semitron ESd 225 (Static Dissipative Acetal)

Semitron ESd 225 is ideal for fixturing used in the manufacturing of hard disk drives or for handling in process silicon water. It is tan in color.

- Surface resistivity: 1010 – 1012 Ω/sq.

- Thermal performance to 107°C

- Good wear resistance

Semitron ESd 410C (Static Dissipative PEI)

Semitron ESd 410c is ideal for handling integrated circuits through the test handler environment. It is black in color and opaque.

- Surface resistivity: 104 - 106 Ω/sq.

- Thermal performance to 210°C

- Low stress for tight tolerance machining

- High strength and stiffness

Semitron ESd 420 (Static Dissipative PEI)

Semitron ESd 420 is the only, truly dissipative plastic product for use in high temperature applications.

- Surface resistivity: 106 - 109 Ω/sq.

Semitron ESd 500 (Static Dissipative PTFE)

Reinforced with a proprietary synthetic mica, Semitron ESd 500 offers an excellent combination of low frictional properties and dimensional stability. Semitron ESd 500 should be considered wherever Teflon PTFE is used. It is ideal for applications where controlled bleed off of static charges is critical. It is white in color.

- Surface resistivity: 1010 - 1012 Ω/sq.

- Thermal performance to 260°C

- Thermally insulative

- Very low coefficient of friction

- Board chemical resistance

Semitron ESd 520HR (Static Disspative Machining Stock)

Semitron ESd 520HR has an industry first combination of electrostatic dissipation (ESd), high strength and heat resistance. This new ESd material is ideal for making nests, sockets and contactors for test equipment and other device handling components. The key features of 520HR are its unique ability to resist dielectric breakdown at high voltage (>100V). The graph below demonstrates the electrical performance of plastic materials commonly used in automated test handlers. Typical carbon fiber enchanced products become irreversibly more conductive when exposed to even moderate voltage.

NYLATRON MC501 R2 AND R6

MC 501CD is a nylon-based compound containing additives which provides superior performance ESD applications. It has constant resistivity at all parts of its body. So, even after being machined, conductivity is unaltered. Even if the surface is worn, resistivity is unaffected. MC501CD never changes its resistivity, while conductive painting products become less efficient. Unlike surfactant-filled plastics, MC501CD never relies on moisture to be effective.

TAKIRON ND7 PVC AND PC

This material is a revolutionary high-performance static discharge plate. It possesses general properties equivalent to those of common rigid PVC plates, ND7 is endowed with anti-static characteristics that remains effective over the very long term, even under tough conditions of use.

- Surface resistivity of 106 - 108 Ω/sq.

- Long term endurance of initial characteristics such as "friction-resistance" and "high electric characteristics and transparency"

- Hardly affected by humidity change.

- Stable surface resistivity against humidity change.

- Excellent chemical resistance and flame retardant.

Established applications:

It can be used various types of equipment in semi-conductor industries. It also finds application in the electronis, electrical, edical, food processing, precision machinery and biotechnology fields, as well as in any other industry where the need to maintain a clean environment exist. Suitable for the structural components of vessel, clean rooms etc.

TAKIRON PC-ND7 ANTI-STATIC POLYCARBONATE SHEETS

By applying ND7 antistatic technology to polycarbonate and taking advantage of its base material's characteristics. PC-ND7 achieves excellent antistatic performance and outstanding impact resistance.

- Antistatic Property: surface resistivity of 106 - 108 Ω/sq.

- Highest impact strength among plastics

- PC-ND7 can also be used at high temperatures. (Deflection temperature under flexural load: 130°C or higher)

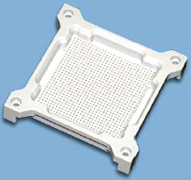

PCB SOLDER PALLET MATERIALS

These materials have helped the PCB manufacturers to reduce solder defects, protect components against heat and electrostatic discharge, increase the productivity and stability of the manufacturing process, and reduce the size of carriers in conjunction with the miniaturizing trends for the PCBs.

CDM ESD 68610

CDM ESD 68610 is a composite material made of glass mat, bonded with a high mechanical resistance resin system.

- Excellent performance at temperatures higher tha 300°C

- Low deformation

- Excellent dimensional stability

- Dissipator material with guaranteed values.

- Surface resistivity 105 to 108 Ω/sq.

DUROSTONE

- CHP760 (Standard Grade, Blue)

- CAS761 (Anti-Static Grade, Black)

- CAG762 (Anti-Static Optical Grade, Grey)

Also Available:

ANTI-STATIC ACRYLIC SHEETS, PVC FILMS and PVC CURTAINS

Services

- Extensive range of high quality engineering plastics at competitive prices

- Products selection advice

- Cut-to-size service on most plastics

- Fabrication of plastics according to your specifications

- High-Precision CNC machine shop services for all types of plastic components

Contact Us

KIMIKA Industrial Corporation

Address: 1857 Maria Orosa St., Malate, Manila 1004

Phone:

02.523.56.41 | 02.523.61.41

02.522.51.53 | 02.522.12.47

02.450.10.22 | 02.420.10.23

Fax: 02.400.27.34

E-mail: inquiry@kimika.com.ph

Find us on Google Maps

sponsored links

SIMILAR COMPANIES/PRODUCTS/SERVICES

Terms of Use/Privacy Policy Advertise Buy me coffee