FTEMI is an internationally recognized enterprise that provides engineering solutions to our customer’s Air, Water and Wastewater Treatment concerns.

We are committed to comply with all applicable environment, health and safety laws, ordinances, standards & procedures and other requirements to which we subscribe.

With more than 20 years in the industry, FTEMI is an enterprise that regards environment, health and safety equally vital and integral part of our customer business

Products

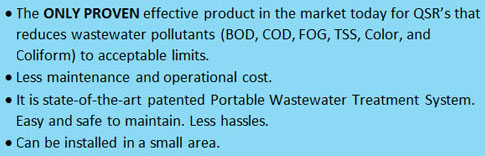

PORTABLE WASTEWATER TREATMENT SYSTEM™

BOD, COD, FOG are the major sources of pollution to our drainage systems, streams, rivers and other receiving bodies of water. FT3 and FT4 models were developed to treat pollutants emanating from Quick Service Restaurants and other establishments discharging low volume.

Products Features:

- Easy Installation: Provided with inlet and outlet connections.

- Versatile and Compact: suitable for domestic and commercial applications.

- Durable and Reliable: Fabricated using stainless steel materials. Durable and corrosion proof.

- Scientifically Designed: Effectively reduces BOD, COD, FOG, TSS, Color, and Coliform within the standard limits set by DENR/LLDA.

- Easy Maintenance: Top access for easy cleaning and removal of trap solids.

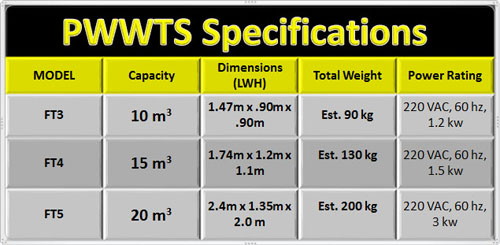

How it Works:

Influent enters the Sump Pit wherein it is aerated and therefore converted into an Equalization Tank. This will be pumped into the first chamber which is the screen basket and oil and grease separator to block other suspended solids and oil/grease in entering the system. Influent now will enter the Aeration Chamber where beneficial bacteria is being fed and cultured to treat the raw wastewater.

Processed water will go to the sedimentation chamber to reduce suspended particles and as well to return activated sludge to the aeration. The wasted sludge is also directed at the same time to the ASD (Activated Sludge Digester) and the overflow (supernatant line) goes back to the Aeration Chamber.

After the sedimentation process, processed water goes to the chlorine contact chamber and then to the Tertiary System for filtration. Chlorine is induced after the Tertiary System for disinfection.

Process Flow Diagram:

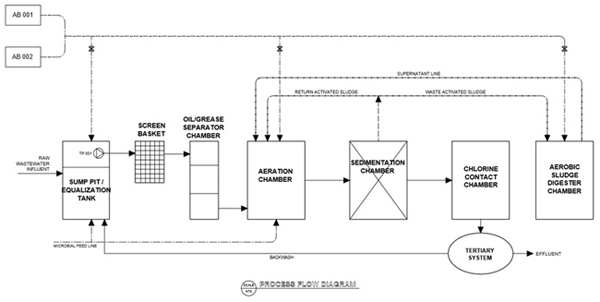

TREATMENT CHEMICALS

Uses and Applications:

- Drinking Water Supply

- Swimming Pool

- Electrolyte

- Boiler Feed Water

- Boiler & Heat Exchanger Tubes

- Cooling Towers

- Water Storage Tanks & Pits

- Sewage Treatment

PROCESS EQUIPMENT

We supply and install specialized equipment and spare parts of different brands for your Sewage / Wastewater Treatment Plant and Cooling Towers.

Air Blowers

Pumps

Dosing Pumps/pH Controllers

Diffusers

Membrane Bio-Reactor System

Mem Bio-series (Membrane Bio-Reactor Systems)

Offering a one-step process for water recycling through the removal of suspended solids and micro-organisms, our Membrane Bio-Reactor Systems help achieve 50% space savings with its economical operation footprint. Through the use of hollow fiber membrane technology, the Membrane Bio-Reactor System may be applied for treatment of sewage effluents and other waste streams with high COD or BOD.

Our Membrane Bio-Reactor Systems are recommended for:

- Remote residential communities

- Estate and property maintenance management

- Cement production factories

- Mining operations

- Decentralized sewage treatment plants

- Industrial estates

Water Softener System

.jpg)

We supply and install Water Softener Systems for various uses such as:

- Cooling Tower feed water

- Steam Boiler feed water

- Manufacturing and Production

- Tertiary Treatment Systems for STP/ WWTP

- Scale and Corrosion Prevention

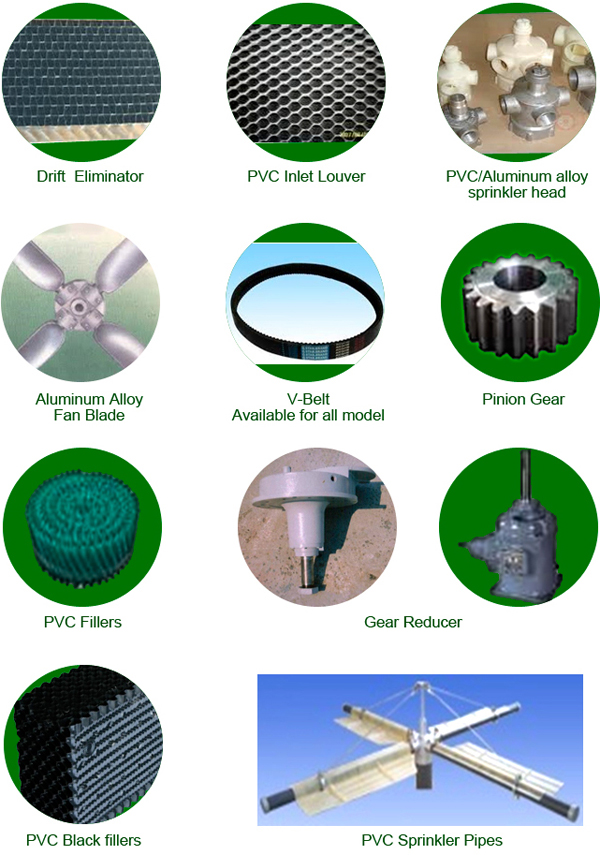

Cooling Tower Spare Parts

CULTURED BACTERIA

For Biological Waste Water Treatment

PROGARD Series

Are scientifically blended concentrates specially selected, adapted and cultured bacterial formulation plus enzymes and special buffers designed to help degrade a variety of compounds and pollutants found in discharged waste waters.

Cultured

C, D, G, O, P, TW, GN, GR

Appearance: Free Flowing Tan Powder

Odor: Yeast-like

Odor Eliminator

AQUAFLOC: In Granules

Progard C and O

Series C - Applications:

Waste containing

- Fatty Acids Residues

- Intermediate length alkyl hydrocarbon

- Residual Alcohol

- Food Processing wastes

Series C - Features:

- Improves BOD and COD removal

- Improves oxygen transfer

- Decreased chemical costs for BOD removal

- Reduction in aeration power consumption

- Rapid shock and kill recovery

Series O - Applications:

Waste water containing

- Heavy grade lubricating oil

- Heavy Machine oil

- Treating fuel oil wastes

Series O - Features:

- Fosters prompt biological detoxification of intrusive chemicals with no harmful side effects

- Reduces concentration of hydrocarbons

- Solves toxic ground spill problems

- Able to adapt to complex and toxic loading in a short period of time

- Improves NH3 remov

Progard D

This is formulated to degrade lignin compounds, complex dyes, etc.

Applications:

Use in different treatment processes:

- Activated sludge system

- Aerobic Digesters

- Trickling filters

- Collection System

- Bio-Towers

- Lift Stations

- Rotating biological disks

- Aerated Lagoons

Features:

- Removal of color

- Enhanced degradation of BOD

- Increase settleability

- Improves Oxygen Transfer

- Degrades Complex Dyes

- Builds Biomass

- Decrease Chemical cost

- Rapid shock and kill recovery

- Degrades lignin compounds

Progard G

This degrades wastes containing petroleum by-products and commercial fuel oils in wastewater.

Series G - Applications:

Waste water containing

- Protein complex waste

- Fats, oil, grease & other dissolved aromatics

- Hydrocarbons linked with amines

- glycerol esters

- Oleaginous waxes and fats

Series P - Applications:

- NS-P- 201- Phenol, phenoxy alcohol

- NS-P- 202 - Organic solvent residue

- NS-P-203 – Aromatic hydrocarbons with hydroxylated

- NS-P- 204 – short chained alkyl hydrocarbons

Features:

- Improves BOD and COD removal

- Improves oxygen transfer

- Decreased chemical costs for BOD removal

- Build biomass

- Reduction in aeration power consumption

Progard TPS

This will digest and liquefy organic wastes in wastewater.

Series G - Applications:

Reduces organic wastes in

- Activated sludge system

- Aerated Lagoons

- Trickling filters

- Aerobic Digesters

- Bio-towers

- Collection Systems

- Rotating Biological wastes

- Lift Stations

Features:

- Improves BOD and COD removal

- Increase system capacity

- Reduces plant operating costs

- Reduces sludge generation & hauling

- Eliminates odors

- Faster supernatant and dewatering

- Build biomass

Progard GN

This cultured anaerobic and facultative bacteria is designed for waste water and sludge.

Series G - Applications:

Organic waste reduction in

- All types of Anaerobic digesters or reactors, Lagoons, Filters and Fluidized bed reactors

- Septic Tanks

- Manure Collection Pits

Features:

- Improves reduction of high BOB & COD

- Faster Supernate

- Removal of H2S

- Improves Reduction of volatile solids

- Odor & color removal

- Lessens scum & grease ball formation

- Increase Methane Gas Production

- The digester

Progard FOG

This degrade protein complex wastes oil and grease, aromatics in wastewater.

Solidified wastes from

- Sinks

- Drainage System

- Lagoons

- Pipelines

- Digesters

- Grease Traps

- Systems

- Toilet Bowls

Reduces organic wastes in

- Activated Sludges System

- Trickling Filters

- Bio-Tower

- Rotating Biological Disks

- Aerobics

- Collection

- Lift Stations

Features:

- Non-toxic, non-caustic, non-corrosive

- Removal of fats, oil and grease

- Eliminates odor problems hue to H2S formation

- Build biomass that will prevent proliferation of harmful bacteria and coliform.

- Prevents disease through contamination

- Reduces crown that alternative methods

- Stop the need for expensive chemicals and mechanical cleaning

Odor Eliminator

This degrade protein complex wastes oil and grease, aromatics in wastewater. Formulated to control malodorsand degrade organic waste from industrial, commercial, agricultural and domestic wastes

Features:

- Reduces odor to its minimum detectable threshold odor concentration (MDTOC) levels

- Reduces hydrogen sulfide

- Liquefies organic wastes

- Non-caustic and non-corrosive

Application:

- Sewage Treatment Plants

- slaughterhouses/Abbattoirs

- Pig/poultry/dairy farm/pet litters

- Solid Wastes Dumpsites/ Landfill

- Stagnant Canals, Waterways, Lagoons

- Commercial Kitchens

- Compost plants

- Garbage Trucks

- Wet Market

- Lift Stations

- Septic Tanks

Aquafloc A810

ANIONIC FLOCCULANT

Works effectively as sludge conditioning agent in numerous solid-liquid separation processes

Application:

- Flocculant

- Coagulant Aid

- Filtration Aid

- Sludge Dewatering

- Clarification of Industrial Raw Waters often in conjunction with inorganic metal salts such as alum

- Municipal Waste Treatment

- Raw sewage settling

- Clarification of primary & secondary effluents

- Alum sludge dewatering

- Polishing & phosphate removal process in tertiary treatment

Aquafloc C810

CATIONIC FLOCCULANT

Is an effective flocculant for Industrial Waste

It clarifies waste water or dewatering sludges from

- Drinking Water

- Metal Finishing/Processing

- Inorganic Pigments

- Paper Processing

- Other Industrial & Municipal Effluent

Services

ENGINEERING DESIGN AND CONSTRUCTION

- Design, Fabrication, Rehabilitation, Construction & Installation of Waste Water Treatment Plant (WWTP) Sewage treatment Plant (STP)

- Design, fabrication and installation of air pollution facilities and equipement

- Evaluation and Selection of appropriate treatment process and design.

- Engineering design calculations to determination sizes and capacities and technical specifications of process, parts and equipment. Prepare for the bill of materials.

- Preparation & submission of detailed engineering drawings, plans & cost Estimates.

- Design, Construction and installation include civil, structural, mechanical & electrical works.

STP/WWTP OPERATIONS MANAGEMENT

We Operate and Maintain Wastewater and or Sewage Treament Plants:

- Supply of manpower, labor and supervision for the daily operation and maintenance of the existing WTP/STP.

- Conducts and performs all activities involved as required by the customer to ensure the system, equipment and facilities are in top running condition and complying to the required regulatory standards of DENR and LLDA.

- Conduct periodic monitoring and recording of the process parameters and other related activities to ensure that such are within required standards.

- Periodic visit of our Qualified Chemical Engineer/Chemist to gather discharge samples for laboratory analysis. Submit to the customer certified written laboratory report as to the actual result

TECHNICAL & MAINTENANCE SERVICES

We provide expertise in performing maintenance services to different industries and establishments.

- Preventive Maintenance on STP/WWTP Process Equipment.

- Repair, Supply and Installation of:

- Air Blowers

- Submersible Pumps

- Dosing Pumps

- Diffusers

- Cooling Tower Maintenance

- Cooling tower operations and maintenance

- Descaling activities

- Scale and Corrosion Prevention

- Implementation of Water Treatment Program

- Boiler Operations and Maintenance

- Boiler Operations and Maintenance

- Descaling activities

- Scale and Corrosion Prevention

- Implementation of Water Treatment Program

- Bio-Augmentation

- Treatment program for kitchen grease traps

- Removal of oil and grease

- Application of cultured bacteria

ENVIRONMENTAL CONSULTANCY SERVICES

- Preparation of Environmental Studies and Reports for the issuance of ECC

- EIS (Environmental Impact Statement)

- IEER (Initial Environmental Examination)

- EPRMP (Environmental Performance Report and Management Plan)

- IEE Checklist

- Preparation of Engineer’s Report as a requirement for the issuance of the ff permits

- DP (Discharge Permit) PTO (Permit to Operate for APSE) Hazardous Waste Generator I.D.

- Assistance to Pollution Control Officers in preparation of their Quarterly and Semi-Annual Reports submitted to DENR-EMB and LLDA

- Facilitates Proponent/PCO with their Application to Permit to Operate for Internal Combustion, Pressure Vessels, etc. to DOLE

- Intermediate consulting services on matters related to the ECC application, compliance to the conditions listed on the ECC and on applicable environmental laws.

- Orientation sessions for PCO and/or with officers concerned regarding EIA System and other specific regulations.

- Monitor, evaluate, test & analyze wastewater/sewage treatment plant effluent laboratory analysis.

- Air Emission for APSE

Clients

Contact Us

Fluid Technologies & Environmental Management, Inc.

Address: No.74 Eraño Manalo Ave. (Formerly E. Rodriguez Ave.), Brgy. Sto. Niño, Marikina City ,1800 Philippines

Phone: (632) 696-7150 | (632) 656-1196

Fax: (632) 696-9421

E-mail: ebc@ftemi.com

Find us on Google Maps

sponsored links

SIMILAR COMPANIES/PRODUCTS/SERVICES

Terms of Use/Privacy Policy Advertise Buy me coffee